Customer inquiry and specification of the general scope & Development of a first concept of a customer-specific process solution

Several presentations of JOEST solutions for the customer

Further development of the process solution details

Decision / order placed with JOEST & Preparation of design drawings

Drawings approved by the customer & Final drawings prepared

Start of manufacturing at JOEST & Regular quality checks

Start of transport of first equipment to Norway & Assembly and installation of first equipment

Manufacturing completed at JOEST

Assembly and installation completed & Completion of construction and installation by other suppliers

January 2016: Cold start-up

April 2016: Warm start-up with product

April 2016: Training of operators and maintenance personnel

May 2016: Service test

May 2016: Final customer approval & Production launch

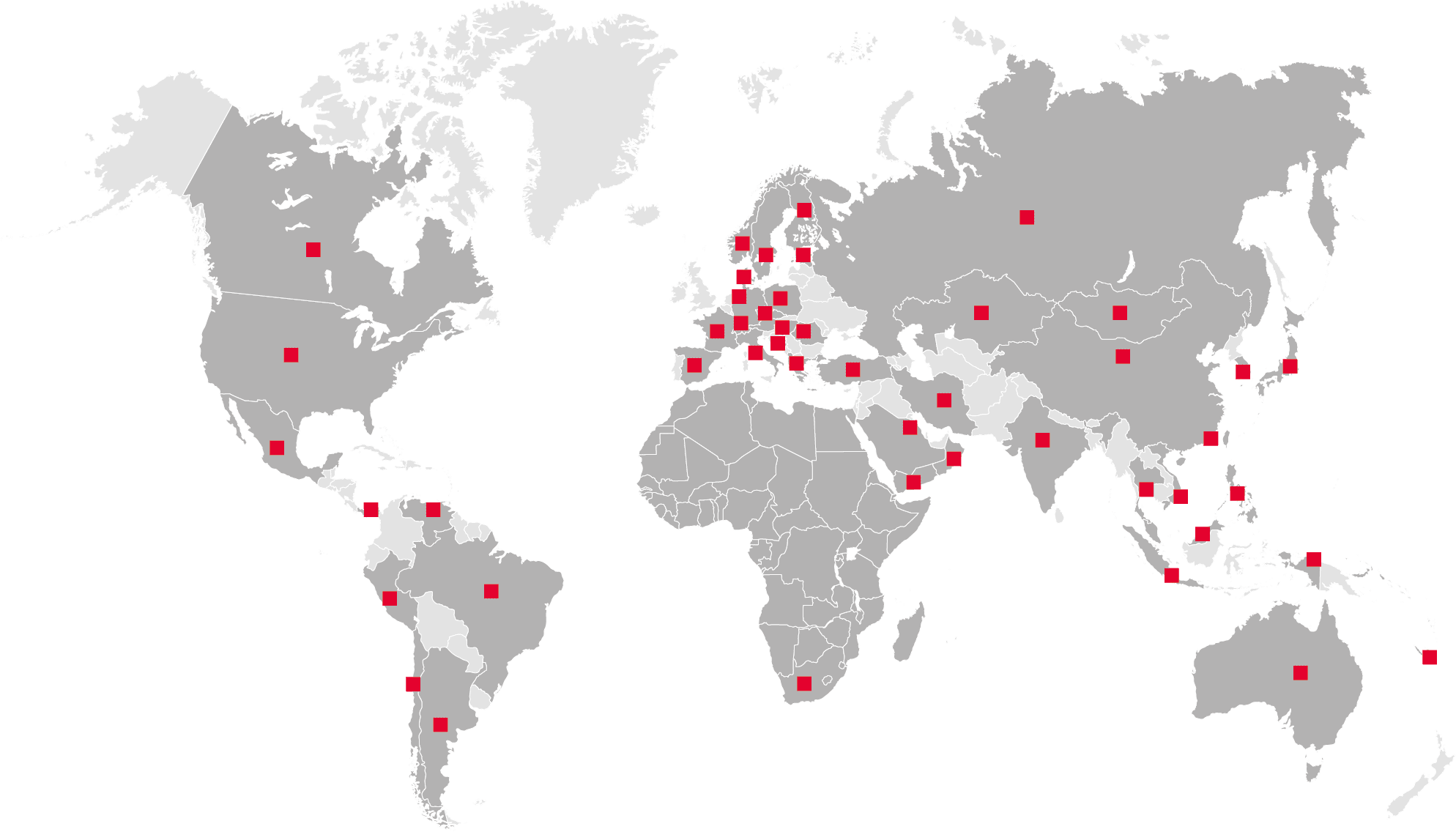

JOEST MINING, MINERALS AND QUARRYING

WHICH SCREEN FOR WHICH APPLICATION?

COMPLETE SUCCESS STORIES

RECOMMEND US